| Dynojet Power Commander III Review

Do you need a fuel injection controller? The Polaris RZR has a fuel injection system whichhelps ensure that the engines performance remains consistent and is virtuallyunaffected by changes in temperature or altitude. This system measurescoolant temperature, air intake temperature, air intake pressure, engine speedand throttle position, then automatically delivers the ideal amount of fuel tooptimize power delivery. Why can’t this high-tech system deal with adding a free flowing aftermarket pipe and/or intake? The simple answer is that unlike automotive applications, a fuel injected UTV does not have a mass air flow meter. Therefore, there is no way to measure the amount of air actually taken in by the engine. The long answer requires a bit more understanding of how a fuel injected UTV works. To run at the optimum level and achieve the highest power output, Dynojet has found that an air/fuel ratio (AFR) between 13.0 and 13.4 to 1 is best. A fuel injected UTV like the Polaris RZR uses a “map” that is built into the ECU to decide how much fuel to deliver at different points of the RPM curve. Various sensors on different systems allow the curve/map to be shifted up or down (richer or leaner) to compensate for altitude and air changes. These sensors do not really change the shape of the curve they just move it up and down a small amount. Even if the fuel curve was perfect on a stock UTV, once you have altered the airflow through the engine (by changing the exhaust, intake, etc.) the table that the ECU uses to deliver the correct amount of fuel no longer matches the altered levels of airflow at different parts of the RPM range. One of the things to keep in mind is that not all modifications increase airflow throughout the RPM range. Often it is necessary to lean out certain areas of a fuel curve for peak output. The best solution to this problem is to allow the user to add or subtract fuel at each 250 RPM increment and throttle position so that the new map matches the new airflow created by the addition of a pipe or intake. Power Commander III: The Power Commander is a fuel injection adjustment unit thatplugs “inline” with the RZRs stock ECU (electronic controlunit). The PC uses original equipment style connectors, so no splicing orcutting of the harness is required. Changes are made to the bikes fuel via thePower Commander’s onboard microprocessor. With this technology, the PCIII offers a large area of adjustment without making any permanent changes to thebikes ECU. Removing the Power Commander returns the bike to its previousstock condition. Each unit comes complete with software and cable link thatallows you to change between different maps or make adjustments to a map file. The competition’s unit can only be adjusted externally and onlymodifies the length or duration of the fuel signal at low, medium and high RPM.Fuel can only be added – there is no capability to lean the curve out. The Power Commander can be adjusted externally for fuel deliveryat low, medium and high RPMs. The Power Commander also utilizes fuel maps thatadjust fuel delivery at every 250 RPM along the entire power curve. Installation: The Power Commander III installation is very simple for the Polaris RZR. It takes about 1/2 hour and installs in-line with no cutting or splicing of wires.

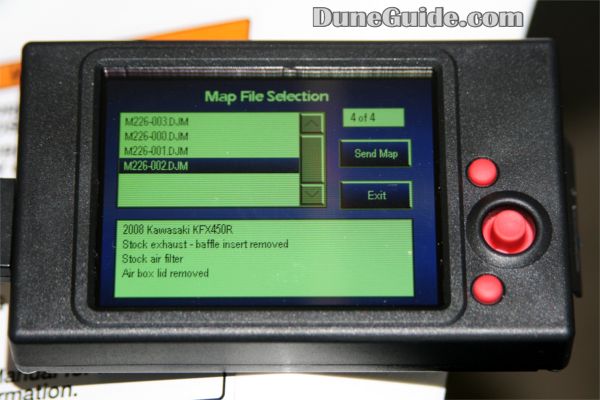

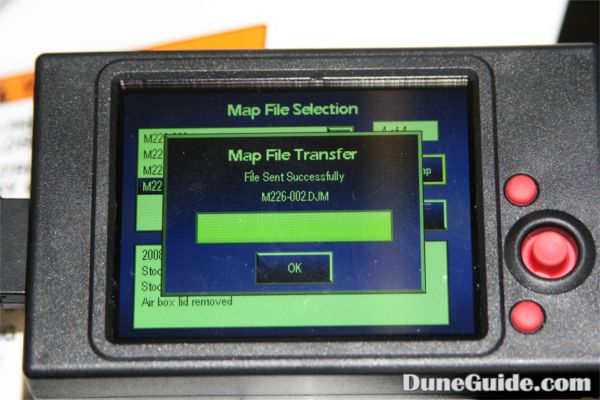

Maps: The Power Commander is supplied with a base map storedin the microprocessor. Additional maps are available via download on www.powercommander.comfor differentpipes and intake configurations. Maps can be shared and tweaked easily over theinternet and downloaded to the Power Commander. Power Commander III – Polaris RZR Maps – Direct link to maps. Using a computer, you can upload alternate maps or make changesto the existing map using the Control Center software and USB cable suppliedwith your Power Commander.

Contact Info:Dynojet Research, Inc. 800-992-4993 Website: www.dynojet.com or www.powercommander.com |

No Comments